Equipped with a thorough understanding of the market and having done research on customer needs and what is missing within the industry in Iran compared to common methods in advanced markets, Lahita Tejarat Company decided to invest in a robotic dry cleaner complex deploying advanced mechanized Italian-made machinery alongside experts to provide high-quality services with world class standards.

The name Ahar (starch) is derived from the materials that were previously used to shape collars and cuffs, which is now done by new methods and advanced machinery in the complex.

With deep knowledge of the world’s famous brands and the importance of differences between various brands and categories of clothes, such as the kind of fabric, sensitivity in the method of washing, and the types of buttons and stitching, Ahar Complex is redefi ning the dry-cleaning industry by revolutionizing the traditional laundry system that used to burn and wear out clothes.

Modern methods have been developed to improve the quality of services and make the software system smarter in providing services and delivering clothes, providing e-invoices in the form of a link, eliminating paper receipts for receipt and delivery of clothes, mentioning the brand alongside photo archiving of the customer’s clothes at the time of issuing the bill, attaching a label with the customer’s identifi cation barcode to re-identify the clothes with the owner’s name, informing the customer of any damages or items left in the clothes, returning the clothes without providing any services (in specifi c cases), outgoing clothes with a smart computer barcode reader system and monitoring of all pieces in the workshop at all times, fastest possible receipt and delivery, English-speaking customer service counter in a 500sqm space in Tehran’s District 1.

Dry cleaning is the process of cleaning clothes and textiles using petroleum- based solvents in cases where water causes damage to the fabric, as well as for clothes with sensitive textures that can’t withstand pressure during washing, rinsing, and drying and can be damaged through traditional washing and ironing processes that many dry cleaners in Iran use. Damages can be caused due to the following reasons:

– Old equipment and a high consumption of perchlorate can cause clothes to be water-cleaned instead of dry-cleaned.

– Lack of enough space in smaller dry cleaners for proper machinery due to their large size.

– Lack of proper equipment in smaller dry cleaners due to unaffordability.

– Non-academic expertise in recognizing different types of fabrics, brands, and various techniques of stain removal.

– Most dry cleaners use a pressing iron which can cause damage to the fabric, discoloration, and make the fabric look worn out due to high temperatures.

solvents from the fabric fi bers a hundred percent, as a result, there will be no trace of bad smell from the used materials and there won’t be any health impacts for customers or operators.

With the help of technology and up-todate equipment purchased from Italy’s RENZACCI and UNION, and the original laundry materials imported by the company itself, standards and quality at Ahar Complex compete with the world’s most advanced countries.

Using a new closed cycle system in machines, with EU and US approval and accreditation, means the solvents used in the dry-cleaning process are no longer removed from the equipment in order to prevent pollution and harm to the environment, the laundry operator, or the customer. Also, low energy consumption and prevention of waste of resources including detergent, all confi rm the eco-friendly aspects of these types of machinery.

The precise engineering and current European standards observed in the purchased machinery and the quality of the raw materials and washing enzymes make for a very high-standard wash at Ahar Complex. Using sensitive washing machines, the washing process is possible for all types of clothing.

The drying process is equipped with a system that can wash feather clothes, pillows and sleeping items and the mentioned clothes can be washed without a change in their shape, form or condition. T-shirts and delicate clothes are dried naturally to maintain their original shape.

Using automatic programs from Europe to raise the effi ciency and productivity levels of the equipment, unlike the Iranian ones used in most dry cleaners which are completely manual, leads to saving on energy, electricity, water, and detergent use.

Using stain removal machines isn’t a common practice in dry cleaners due to the bulky and expensive machines and raw materials. At Ahar Complex, a special stain removal machine is used for each of the dry cleaning and bleaching methods, because the specifi c stain removal materials differ depending on every method of dry cleaning or washing. The stain remover solutions used by Ahar Group are therefore from the very best European brands.

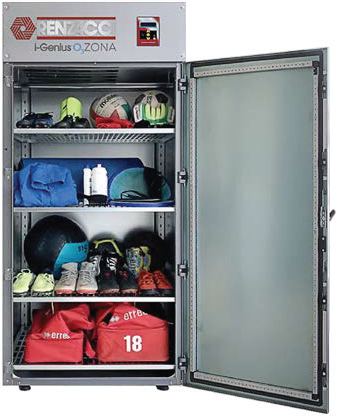

Aiming to improve the hygiene level of the dry-cleaning process for the fi rst time in Iran, Ahar Group has brought about a revolution in the dry-cleaning industry, by using an advanced, fully specialized antibacterial and textile sanitizing device. Using UV technology and ozone (O3), this device eliminates the bad smell of cigarettes and substances that can’t be removed by the washing process. It is also able to remove viruses, bacteria, mold, fungi, and allergenic dust.

The items that can be disinfected include baby accessories, strollers, woolen and plastic dolls, blankets, pillows, boots, helmets, gloves, mountaineering gear, and skiing equipment.

The ironing process at Ahar Complex is done in a completely specialized way using modern pressing mannequins.

Each garment in this complex is pressed using an iron mannequin (pants, collars and cuffs, shirts, coats, and t-shirts).

The differences between these mannequins and the traditional presses are; the absence of electrical shocks and fabric burns, no discolorations, no cresses on pants even the sides, shaping the edges of pockets, absence of sagging shoulders, correct shaping of the collar and shoulders, no damage to the buttons, no changes in the size or shape of sensitive clothes, no damage to the images or labels, etc.

This process is done by hand for all clothes at the end, just like seven-star hotels.

Mending and sewing, are done by the most experienced tailors at this complex

Washing all kinds of formal or sports shoes.

Waxing and polishing leather and varnished shoes with the highest quality materials by the best brands in the world.

Serving premium coffee with Italian coffee machine.

Ahar Group is expanding its business to provide services to more clients soon. At this time, we feel it is appropriate, to thank all those who have helped the complex to reach its current position in such a short time, especially the Hally Group for their unwavering support.

Manager & Co. Founder:

Hamed Samani

Graduated with a Master’s Degree

in Entrepreneurship from Allameh

Tabatabaei University

MBA Certifi cate from University of

Tehran

Founder :

Reza Dehghani Mofradpour

No.1, Alef St., Velenjak Blvd.,

Thran- IRAN

Phone: 0098 21 720 96

Instagram: @aharlaundry

Opening Hours:

24/7

Phone: +90 531 640 4133

Email: info@trendzmena.com

Address: TRADEX INTERNATIONAL CONSULTING DANIŞMANLIK

itH. iHr. ve TiC. LTD. ŞTi.

Tomtom Mah. istiklal Cad. Beyoğlu iş Merkezi No.187 iç Kapr No: 4 Beyoğlu/iSTANBUL Beyoğlu V.D. 8591125255