By: Trends Editorial Team

Behzad Haji Shirmohammadi, was born in 1969. He has a bachelor’s degree in civil engineering from Iran University of Science and Technology. Shirmohammadi started his career by working for Charman Company as a site supervisor. His subsequent posts were as site manager for the Iran Industrial Development Renovation Construction Co. and later at the Pars Civil Union Company. He finally joined the Kayson family in 2006 and started working on various projects as a project manager for several years. His assignment as the project manager of Iran Mall in 2014 at Kayson led to his promotion to CEO of the Omran Kayson Company where he has been serving since 2019.

Behzad Haji Shirmohammadi, was born in 1969. He has a bachelor’s degree in civil engineering from Iran University of Science and Technology. Shirmohammadi started his career by working for Charman Company as a site supervisor. His subsequent posts were as site manager for the Iran Industrial Development Renovation Construction Co. and later at the Pars Civil Union Company. He finally joined the Kayson family in 2006 and started working on various projects as a project manager for several years. His assignment as the project manager of Iran Mall in 2014 at Kayson led to his promotion to CEO of the Omran Kayson Company where he has been serving since 2019.

Thank you so much for giving Trends this exclusive interview despite your busy schedule. We are very grateful. Please tell us about the founding of Kayson and its achievements to date.

Kayson Inc. was established in 1975 with the goal of construction in the residential, commercial, and urban infrastructure sectors. The company has more than four decades of successful experience in implementing large development projects such as oil industry complexes, gas and petrochemical plants, industrial factories, roads, highways, underpasses, tunnels, dams, airports, irrigation and drainage networks, subways and water and sewage transmission and treatment systems, and also in building residential and commercial complexes.

Kayson is one of the leading private sector companies in the country in general contracting and engineering, procurement, and construction (EPC). In order to develop its supply chain within a holding company concept, Kayson created a network of companies early on and still carries out its projects under that umbrella. Kayson seems to have been involved in the Iran Mall project from its inception and tender phase through its actual operation. Please give us a description of the whole process including project size, volume of work, types of contracts and your project oversight experience.

In 2014, Ayandeh Bank chose Kayson as the main contractor of Iran Mall based on its domestic and international prestige and success. For this project, Kayson made every effort to optimize the initial designs, broaden local engineering knowledge of all aspects of commercial complexes, promote utilization of local materials, and improve domestic technical expertise.

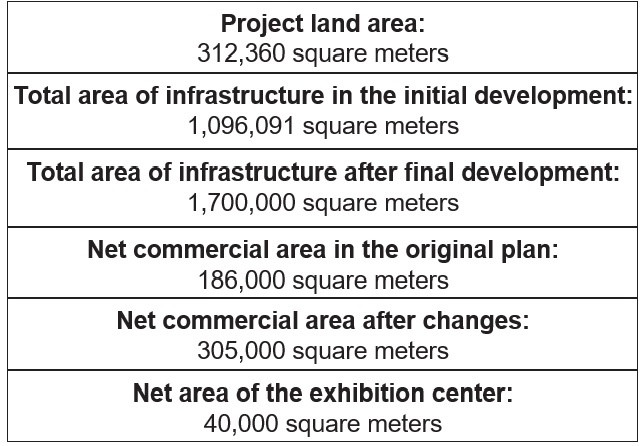

This giant project with more than 2,000 sub-contractors, suppliers and consultants who were working under the supervision of Kayson as their contract manager, was executed in a methodical and efficient fashion and delivered on schedule to begin operation. I believe this goes to show the company’s ability to carry out large projects with diverse dimensions expeditiously and on an international scale in our country. The project size is in

accordance with the table below:

Please provide a brief explanation of the contract acquisition, selection of sub-contractors, consultants, and suppliers for the Iran Mall project. Once the contract was signed with Ayandeh Bank, we drafted a tender document detailing the required goods, works and services of suppliers and proposed list for selection of contractors from Kayson’s vast network of vendors. The proposal was readily approved by the bank, and its technical team. Next phase consisted of numerous meetings with the bank as well as our technical consultants for the final selection of sub-contractors, agreements on pricing, and other aspects of the project in accordance with the approved proposal. Note that for selection of sub-contractors, the list of vendors evaluated and recommended by Kayson was what was being considered. For a project of this vast size and with this huge volume of requirements as the Iran Mall, the country’s top-ranking construction and infrastructure contractors were assembled to build its basic physical and organizational structures and facilities. In addition, due to the breadth of the project in its other elements such as extra-low voltage electrical system, fire detection and alarm systems as well as unique spaces and features of the mall, contractors with specific expertise were selected. The proficiency of these skilled contractors together with the seamless and professional management of Kayson as contract manager, resulted in a successful project and a world-class mall. As general contractors of the project, Kayson was involved in the design and engineering process of the Mall. You also dealt with domestic and international consultants to bring the project to fruition

Please explain your experience working with such diverse array of people, and how you were able to integrate the original design with local architectural elements?

The initial design of the complex was done by the Canadian company, NORR. About 2,500 sheets of drawings provided by NORR were first reviewed by the Iran Central Core of Engineers upon the requests of the Ayandeh Bank, or the client, to adapt the architectural style of the proposed design to Iranian architecture. In tandem, Kayson prepared about 23,000 new plan blueprints with the help of its design and architecture consultants, both domestic and foreign, who numbered around 50 in total. For this work, a new unit called “field engineering” was created within Kayson in order to oversee the necessary coordination among outside consultants, company executives and the technical units. Due to the size of the project and construction conditions, finished initial design plans were re-submitted to the execution unit for on-site review. Finally, minor changes to the drawings were recommended and agreed upon by the parties and necessary modifications were made by the engineering unit. Our experience demonstrated that in large-scale projects, having in-house field engineering units is important and necessary for coordination and building of consensus among executive units, and for support of outside engineering teams. For an elaborate and intricate project like Iran Mall, relevant sub-contractors were typically given the project plans ahead of time to review and consider in case of any discrepancies with respect to on-site work. All unresolved questions and any changes regarding the designs or work to be done were passed on to appropriate technical teams to be addressed and dealt with. And once again, field engineering units approved the final plans in follow-up meetings, and new directives were then sent out to relevant sub-contractors.

Please give a brief explanation about the effects of Building Information Modeling (BIM) used before the start of the project, during implementation, and finally with respect to operation of the complex.

One of our successful experiences in this project has been the use of BIM. Considering the specs of the Iran Mall project, with its large-scale construction size and vast area, and also in terms of the number of individuals and companies active in the project, it was decided early on that it would be best to take advantage of BIM. As for its implementation, an Autodesk software program called Revit was selected as the main tool of the project. But the real challenge in implementing BIM remained its lack of utilization in similar projects until then. To accelerate the process, training in BIM for different levels was started first with the management of Kayson. The priority was to train for Revit software experts which in turn would accelerate the implementation of BIM. Before the start of the project, there were a handful of people proficient in BIM technology and Revit, but eventually about 300 architects, structural and installation engineers were trained in this system and mastered the Revit software. Once initial architectural plans and design of facilities were finished, they were provided to relevant contractors. Next, digital drawings were modeled, and any discrepancies were sorted out and altered to comply with technical and executive requirements, and compatible with architectural details. Subsequently, each plan was reviewed with representatives of different departments of the Engineering and Execution group in a joint meeting and any incompatibility issues with respect to engineering standards were addressed. Then the forecast of maintenance conditions was re-examined, and issues resolved, and the project was confirmed for fulfillment. Taking these measures significantly improved the prioritization process and reduced delays in implementation, accelerated conflict resolutions and favorably impacted the financial costs and efficiency of the project, compared to other similar enterprises.

By consolidating the system files related to each area into one file, everyone working on the project was able to benefit from an integrated 3D model of all project spaces with the necessary details.

Due to the fact that Iran Mall is the largest commercial center project in Iran and new construction methods have been used, do you have a way to record these experiences for Kayson and those interested in this field?

Kayson, as one of the leading international general contractor companies in Iran, has considered management as a form of acquired knowledge and as one of the main pillars of its project management in all stages of development. Given the mission of “development at a global level,” Kayson is committed to quality implementation of their projects, and this requires the transfer of experience and knowledge from one job to another in order to improve the caliber of every project. The size and multitude of elements of the Iran Mall project, many of which have been implemented for the first time in the country, have turned this project into a valuable treasure trove of knowledge.

To organize accumulated implementation know-how, the knowledge management team has compiled all data regarding the project and examined it with leaders of relevant project units in accordance with the AAR (After Action Review) procedures. Ultimately, the vast amount of experiences and lessons learned in commercial project management related to Iran Mall were assembled under titles as executive and management manuals some of which have already been published, with others soon going to print.

It is worth mentioning that in addition to the aforementioned books, a wide range of information related to the Iran Mall, from the initial project phase to the time of operation, including original plans, technical specifications, phase two maps, operational information, etc., have been gathered and put together in form of

a single handbook which is an overview of the various stages of the project.

Please describe your method for completing and delivering the project to the project sponsor and operating management.

By developing and implementing Inspection and Test Plans (ITP), adhering to quality control guidelines and completing checklists at every phase of the process, and following operations permit protocols, Kayson inspected the performance of all project sub-contractors for maximum quality control to prevent any defects and problems at the time of delivery. In addition, according to the scope of activities as well as the project’s unique spaces and operating conditions, the job was divided into different sections and disciplines so that each part could be delivered and operated separately according to its assignee.

To accomplish this, working groups were formed with representatives of the client, outside consultants, contract managers and sub-contractors, and even sometimes the corresponding vendors. At the time of delivery of each phase or space, applicable punch lists were reviewed and all and any issues addressed in such a way that said area/ job would be delivered ready for operation.

It should be noted that as requested by the client, the final handbook of the project included collected information about the project in an integrated manner and with search ability in the form of an all-inclusive software. The location of all project equipment as well as all related data including purchase information, certificate of authenticity of goods, test results, technical specifications and relevant information sheets are included in this software, with links for installation and service instructions and a list of spare parts.

As one of the largest companies in the construction industry, what is your recruitment process?

In order to provide a workforce in line with Kayson’s strategy of “securing an able pool of personnel,” human resources management selects employees based on organizational competencies, and corporate principles and values. It is worth mentioning that a sense of responsibility, teamwork spirit and relevant training for job requirements are the priority of the recruitment process. One of the principle goals of the company is to broaden the level of staff skills through approved training courses. All job applicants can refer to the Kayson HR recruitment website and after reviewing the list of our job opportunities, applicants can complete and submit an employment questionnaire. In addition, the company uses other channels of recruitment such as employment agencies and job advertisements in national newspapers.